Why Do Some Acrylic Standees Smell Like a Chemical Accident? (And How We Fix It)

Have you ever opened a package of Custom acrylic stande […]

Turn your designs into huggable reality. We specialize in high-quality custom Dakimakura and branded cushions with premium 2Way Tricot & Peach Skin fabrics. Low MOQ, factory-direct pricing.

We offer free acrylic standee mockups before production to help you visualize the final product.

No design? No problem. Our in-house team helps you design your custom standee from scratch.

Start small – our acrylic standee custom manufacturer services support low MOQ from just 50pcs.

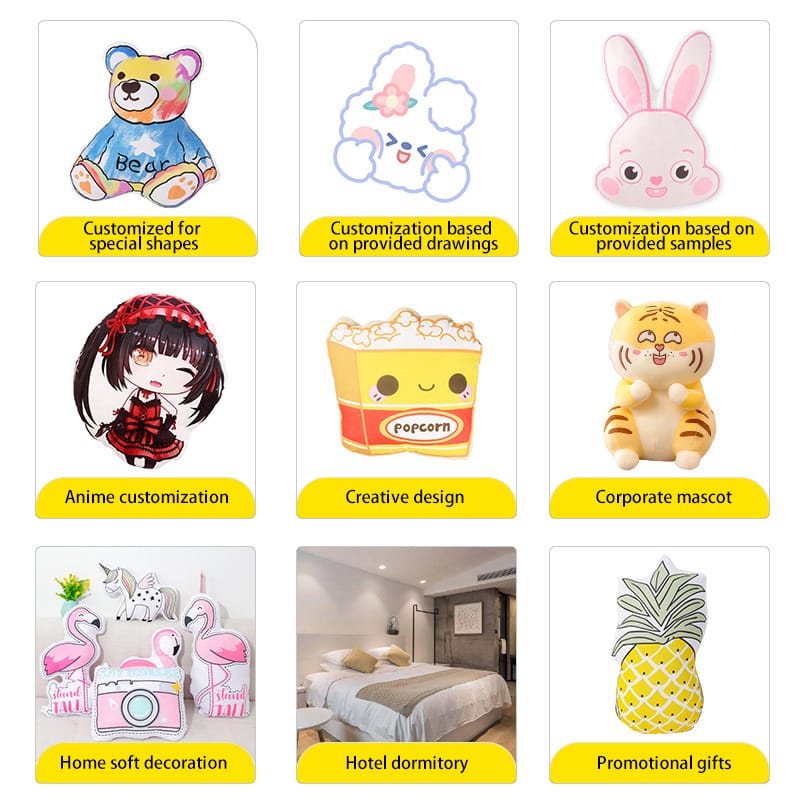

We are not just a pillow printer; we offer a wide range of shapes and styles:

Dakimakura (Body Pillow): The standard 150x50cm / 160x50cm sizes for anime fans.

Standard Throw Pillows: Square shapes (40cm/50cm) for home decor and branding.

Die-Cut Shaped Pillows: Custom contour shapes following your character or logo outline.

Mini Keychain Pillows: Small 10cm plush accessories.

At Bocegifts, we understand that the “touch” is everything for custom pillows. We offer two primary fabric options to match your market positioning:

feature Block A: 2Way Tricot (The Collector’s Choice)

Best For: High-end Anime Dakimakura and premium merchandise.

Texture: Cool, smooth, and skin-friendly.

Elasticity: High 4-way stretch. As shown in the image, the fabric recovers instantly after stretching, preventing deformation.

Color Payoff: Delivers the highest color accuracy and depth for complex anime character designs.

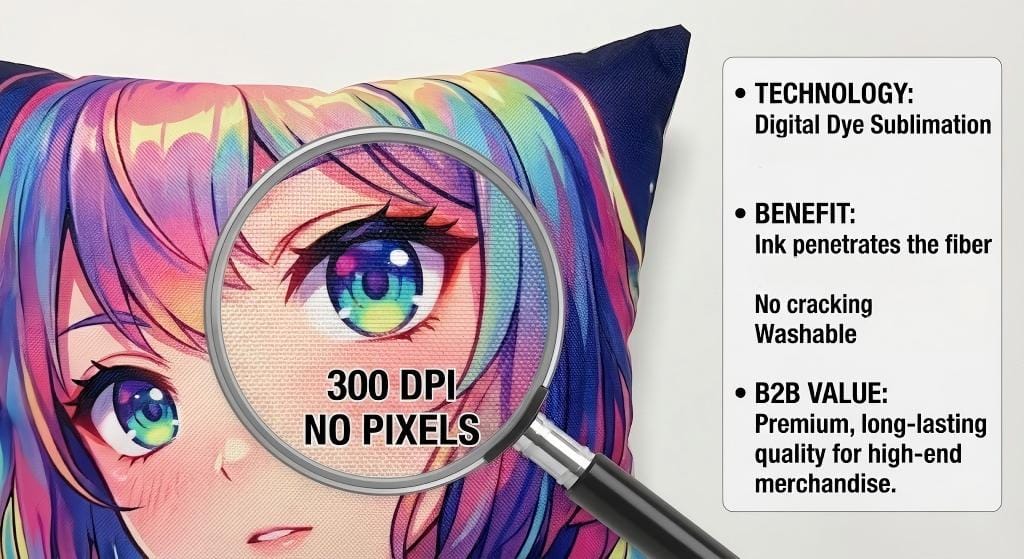

Don’t settle for cheap surface transfers that crack and peel. We utilize advanced Digital Dye Sublimation technology where the ink penetrates deep into the fabric fibers at high temperatures.

Why Our Printing Stands Out:

300 DPI High Definition: Every detail, from the character’s eyes to gradient logos, is sharp and pixel-free.

Zero “Hand Feel”: The print does not change the texture of the fabric. You can’t feel the ink—only the softness of the pillow.

Permanent Bond: The image becomes part of the fabric. It will never crack when stretched and is 100% machine washable without fading.

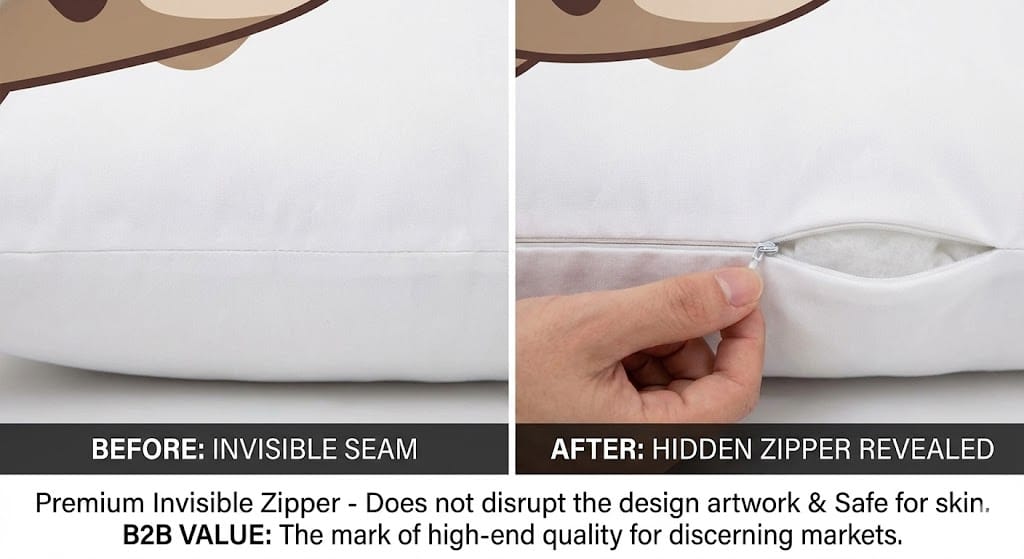

Quality is defined by details. Unlike standard pillows with bulky, exposed zippers that disrupt the artwork, Bocegifts uses a premium Invisible Zipper system.

Seamless Aesthetics: The zipper is hidden at the bottom seam, ensuring your “Front” and “Back” designs are displayed perfectly without interruption.

Safe & Comfortable: The tiny zipper head is tucked away, ensuring it never scratches the skin or catches on hair.

Retail Ready: This high-end finish commands a higher retail price for your brand compared to standard “exposed zipper” products.

International shipping is the biggest pain point for B2B buyers. We solve this with our industrial Vacuum Compression Packaging.

The “Volume” Advantage:

Before Compression: A standard pillow insert takes up approx. 0.05 CBM.

After Compression: We reduce it to a thin sheet, approx. 0.01 CBM.

The Result: You can ship 5x more product in the same carton, saving up to 70% on shipping costs. The pillows fluff back up instantly upon opening.

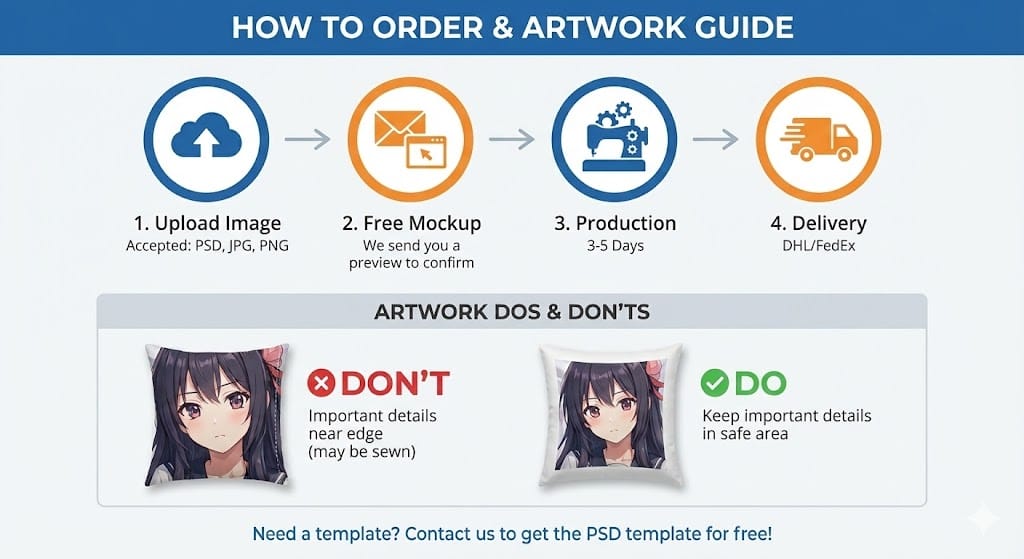

Step-by-Step Guide:

Upload Image: Send us your design in PSD, JPG, or PNG format. (Resolution > 1500px recommended).

Free Mockup: Our team will adjust your file and send a digital preview to confirm sizing.

Production: Fast turnaround time of 3-5 working days for production.

Global Delivery: We ship via DHL/FedEx/UPS straight to your warehouse.

⚠️ Artwork “Do’s & Don’ts”

❌ Don’t: Place important details (like faces or text) too close to the edge. They may be cut off by the sewing line.

✅ Do: Keep main subjects within the “Safe Area” (at least 2cm from the edge).

Need Help? [Contact Us] to download our Free Standard Dakimakura PSD Template with bleed lines included.

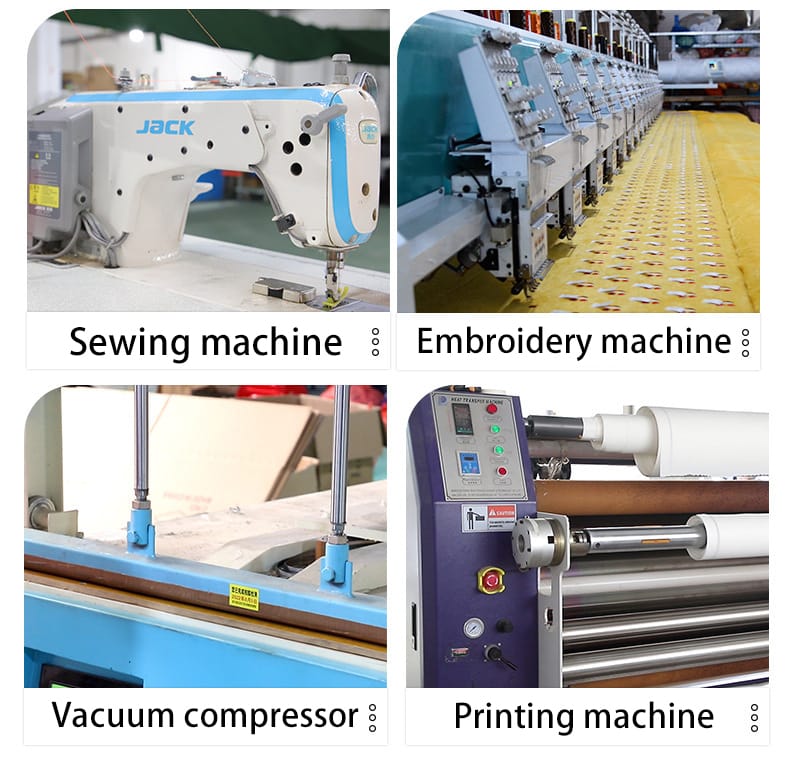

1. High-Speed Digital Sublimation Printers (Printing Machine)

The Tech: Equipped with industrial Epson print heads supporting 8-color gamut.

The Benefit: Delivers photo-realistic print quality at high speeds. We can produce up to 5,000 meters of printed fabric per day, ensuring your rush orders are met on time.

2. Industrial Lockstitch Sewing Machines

The Tech: Computerized auto-trimming sewing units.

The Benefit: Ensures tight, double-stitched seams that won’t burst, even under pressure. Our skilled operators have an average of 5+ years of experience handling delicate fabrics like 2Way Tricot.

3. Precision Embroidery Machines

The Tech: Multi-head computerized embroidery systems.

The Benefit: Perfect for adding brand logos, woven tags, or special textured details to your promotional cushions. Adds a high-value, tactile feel to your product.

4. Industrial Vacuum Compressors

The Tech: Heavy-duty hydraulic compression sealers.

The Benefit: Compresses bulky pillows into flat, airtight packages. This machine is the key to helping our B2B clients reduce volumetric weight by 70%, making international air freight affordable.

1. Precision Laser Cutting Workshop

Process: Automated laser cutters slice through the fabric based on digital patterns.

Why it Matters: Unlike manual cutting, laser cutting seals the fabric edges instantly (cauterization), preventing fraying and ensuring every pillow shape is identical to your design file.

2. Automatic Cotton Stuffing (The “Fluff” Factor)

Process: We use high-pressure blowing machines to fill pillows with premium 7D/15D PP Cotton.

Why it Matters: Ensures uniform density without lumps. Your pillows will remain fluffy and resilient, avoiding the “flat pillow” complaint common with cheap suppliers.

3. Quality Inspection Workshop (100% QC)

Process: A rigorous 3-step inspection before packaging.

Visual Check: Checking for print defects or color shifts.

Stress Test: Pulling seams to ensure durability.

Metal Detection: CRITICAL FOR SAFETY. Every pillow passes through a needle detector machine to ensure no broken needles are left inside. This is mandatory for US/EU safety compliance.

Have you ever opened a package of Custom acrylic stande […]

So, you want to order ? Great! Perhaps you are finally […]

I. Product Realization: How to Manufacture High-Quality […]

Contact us today, and our team will respond promptly. We are always dedicated to meeting your expectations and exceeding them. Fill out the form now!

Looking for distinct promotional products? BOCE Gifts delivers a wide variety of customizable options, from silicone bracelets and patches to woven tags, helping businesses create memorable brand experiences

2026 Suzhou Boce culture Promotion Gifts co.Ltd.

Terms &Conditions