I. Product Realization: How to Manufacture High-Quality Acrylic Standees

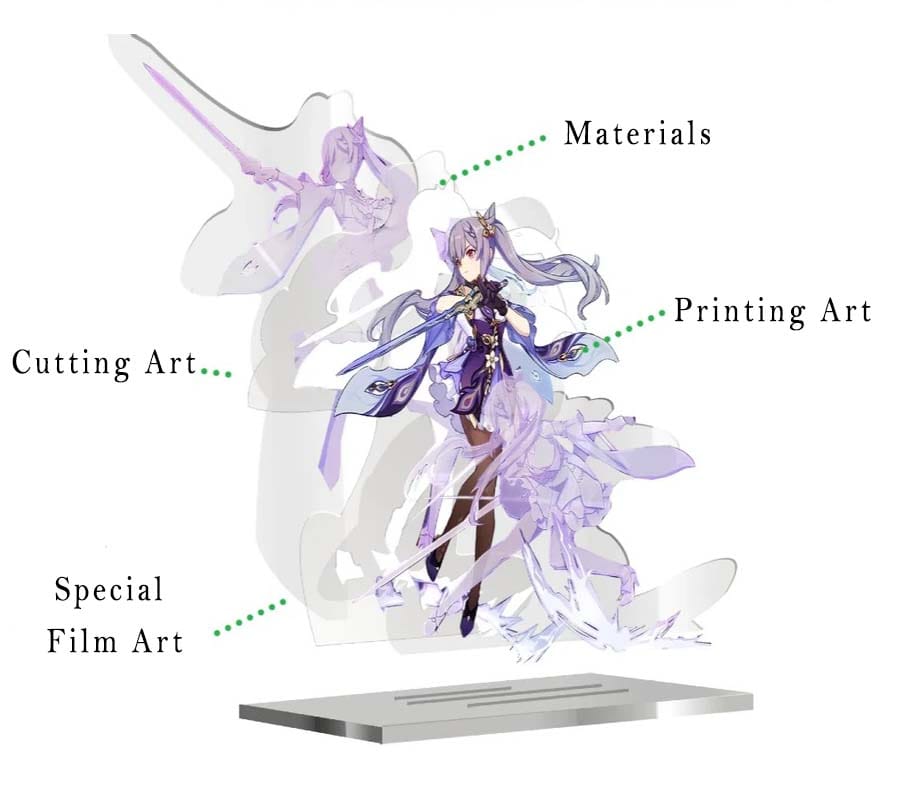

How do you bring a standee product to life? To become a top-tier custom acrylic figure maker, one must realize that a great standee relies on more than just excellent creative design; it is strictly constrained by manufacturing elements.

This guide explores the four dimensions essential for any acrylic standee manufacturer: Materials, Printing Processes, Cutting Processes, and Special Film Crafts.

Design is key, but Material & Craft come first!

No matter how good the design is, if you don’t understand basic product knowledge, even the best acrylic standee supplier cannot guarantee a perfect result. Mastering the knowledge of materials and craftsmanship is a fundamental skill for producing high-quality custom acrylic standees wholesale.

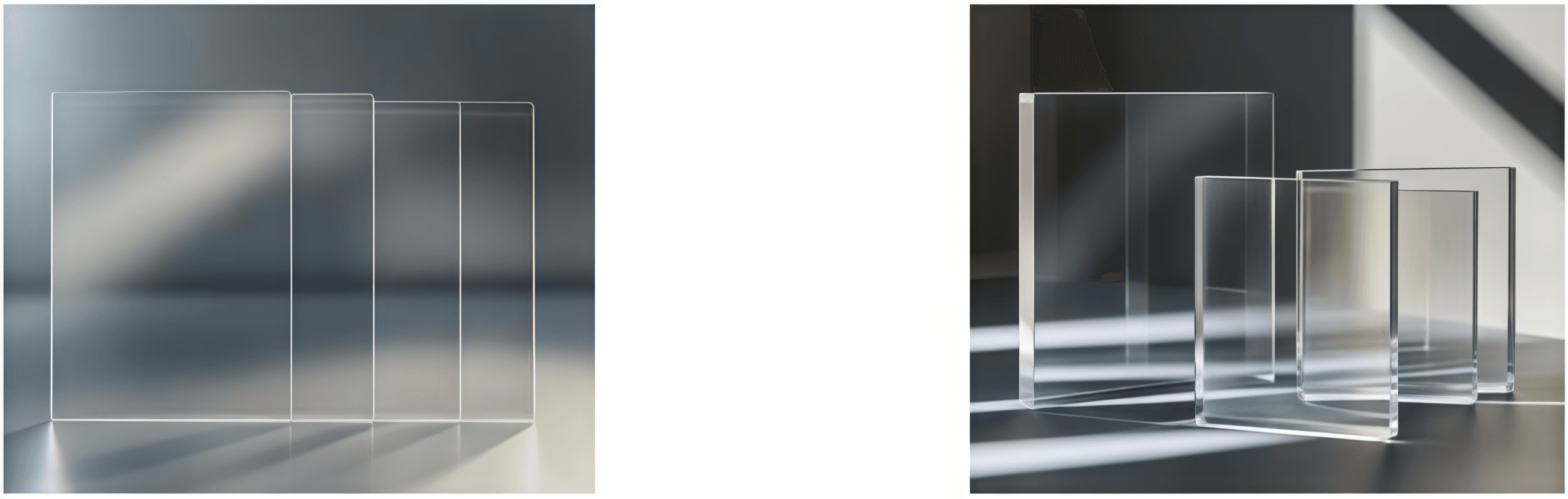

II. Mainstream Materials (PET vs. Acrylic)

About Mainstream Materials

Currently, the transparent card materials on the market are mostly PET (also referred to as PVC by some merchants) and Acrylic. Both are loved by creators for their good light transmission and plasticity.

Material Comparison Table

| Feature | PET/PVC | Acrylic |

| Standard Thickness | 0.5mm | 2mm |

| Translucency | Slightly inferior | Ultra-high transparency |

| Hardness | Soft, bendable | Hard, solid |

| Coloring | Brighter/More Vivid | Relatively muted |

| Composite Structure | Standard single layer | 1+1 or 2+1 Sandwich layers |

| Cost | Lower | Higher |

| Packaging | Standard single-sided film | Double-sided film |

PET/PVC Detailed

-

Characteristics: Transparent resin material. The standard market thickness is about 0.5mm. Its light transmission is slightly lower than acrylic. It is lighter and thinner than acrylic, making printed colors appear brighter. The material is soft and can be slightly bent.

-

Structure: Typically a single layer of 50-micron PET plus a lacquer finish. There is also a sandwich process called “Imitation Offset PVC,” which uses a 50-micron PET + Printing Layer + 10-micron PET. Compared to the single-sided PET process, the thickness is 0.6mm, making it stiffer, and it has double-sided film for better protection.

-

Cost: PET material prices are lower than acrylic, making it the first choice for those with limited budgets looking for bulk acrylic standees.

Acrylic Detailed

-

Characteristics: Standard market thickness is about 2mm. It has excellent light transmission. It is harder than PET, feels solid, and light refracts when passing through it. Colors are relatively more muted compared to PET.

-

Structure: Can be made as a 2mm single layer, or as 1+1 or 2+1 sandwich layers. Acrylic has double-sided film for better protection.

-

Cost: The cost of acrylic is higher than PET.

III. Acrylic Board Selection (Cast vs. Extruded)

Choosing the Right Acrylic Material

Any professional acrylic standee manufacturer knows that acrylic materials are divided into Cast Boards and Extruded Boards. Different boards have different characteristics. Before production, you must understand these properties to better restore the features of the design.

Material Comparison: Cast vs. Extruded

| Feature | Cast Board | Extruded Board |

| Process | Liquid MMA raw material via casting process | Solid PMMA granule raw material via extrusion process |

| Hardness | High hardness, weather resistance, strong mechanical properties | Better machining performance, high flexibility, good for bending and thermoforming |

| Thickness Tolerance | High | Small |

| Transparency | 96% or more | 92% or more |

| Edge | Very transparent | May have pockmarks; B-grade boards show yellowing/blackening at edges |

| Color Freedom | High | Relatively low |

| Chemical Performance | Extremely high strength and UV function | Decent strength and UV function |

| Standardization | Complete specifications, high color freedom | Color and specifications are standardized |

| Stability | Long service life | Colors fade and material becomes brittle under light exposure |

Acrylic Cast Board Detailed

Uses MMA monomer (liquid) directly cast into shape. With its high molecular weight, it exhibits excellent stiffness and strength, along with outstanding chemical resistance. This board shows unparalleled flexibility in small-batch production, especially in color systems and surface texture effects, meeting diverse design needs.

-

Product specifications are complete and widely suitable for various special uses.

-

Cast boards not only have extremely high strength but also powerful UV protection, ensuring a long service life in outdoor environments.

Acrylic Extruded Board Detailed

Extruded boards are formed by squeezing granule raw materials after high-temperature melting. They have higher flexibility and a shorter softening time, making them easy to process. Compared to cast boards, they have a lower molecular weight and slightly inferior mechanical properties. However, this feature is an advantage in bending and thermoforming, especially for rapid vacuum blister molding of large-sized sheets.

-

Smaller thickness tolerance is another significant feature.

-

Because it is large-scale automated production—ideal for bulk acrylic standees—extruded boards are limited in color and specification adjustments.

-

Most extruded boards do not have UV protection, leading to a much shorter outdoor life than cast boards, with colors prone to fading and brittleness.

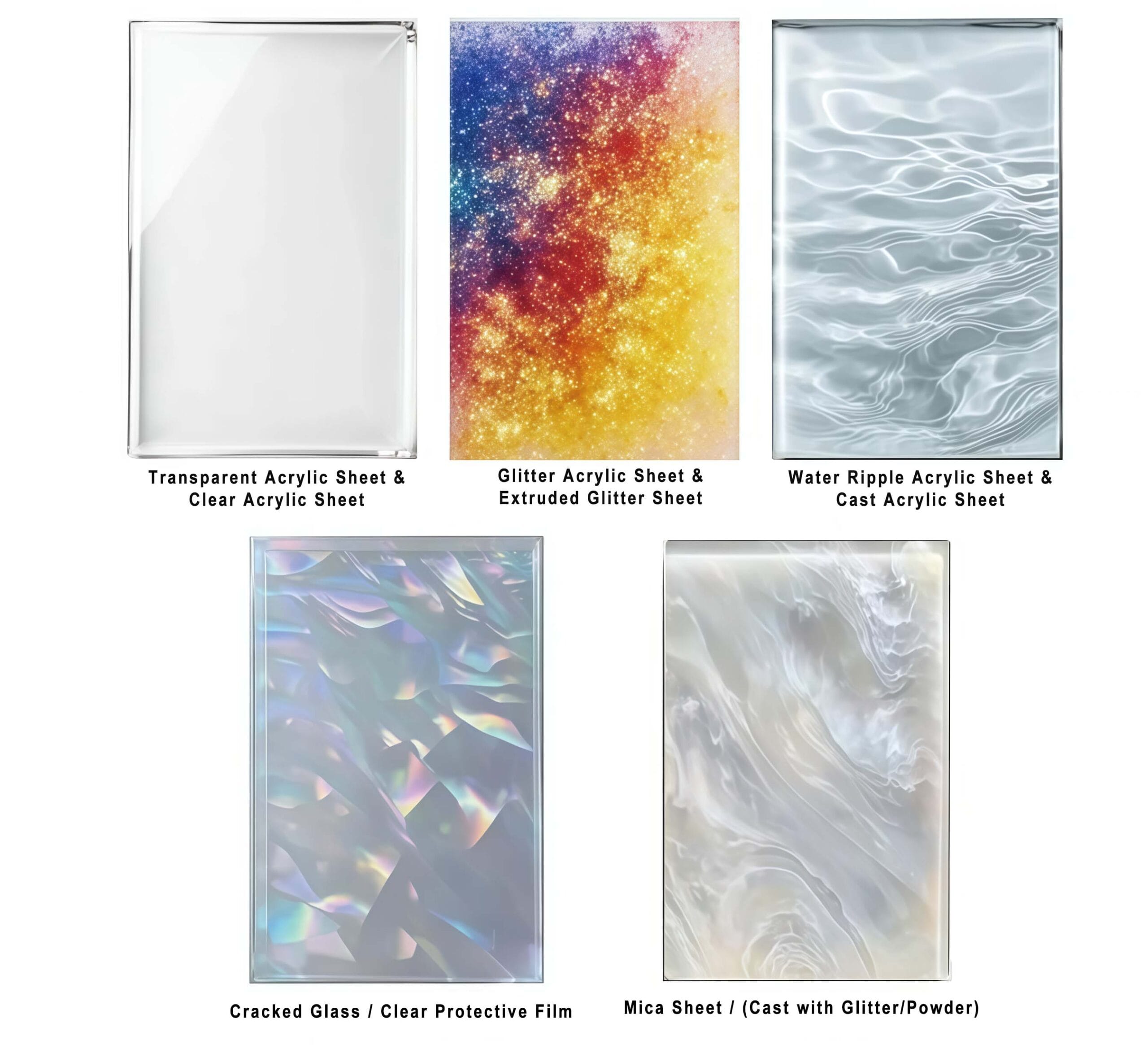

Common Acrylic Board Types

Transparent Board ,Glitter Board / Extruded with Powder,Water Ripple / Model Casting,Broken Glass / Transparent Film,Mica Board / Cast with Powder

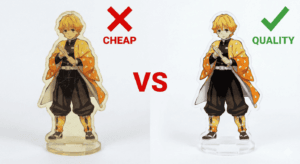

IV. Printing Processes

About Printing

A premium acrylic standee printing service typically uses Inkjet, UV Printing, or Offset Printing. Costs vary greatly depending on the process, so it is important to distinguish them.

| Feature | Inkjet Printing | UV Printing | Offset Printing |

| Suitable Material | PVC/PET | PVC/PET, Acrylic | PVC/PET, Acrylic |

| Ink Thickness | Thin | Thick | Thin, smooth feel |

| Adhesion | Low | High | High |

| Granularity | Fine watermark dots | Noise/Grain | Precise regular mesh |

| Color Saturation | Relatively gray | High Purity | Relatively gray |

| Edge | Watermark dots blurry | Noise blurry, soft | Clear/Sharp |

| Color Contrast | Standard | High | Natural |

| Cost | Low | Low (Customizable for singles) | High (Batch production) |

| Setup | None | None | Requires Plate Making |

Process Details

-

Inkjet Printing:

-

Common in digital print shops or home printers.

-

Ink is thin with low adhesion; paint easily chips off after long-term storage or scratching. Close inspection reveals fine watermark dots and slight ink sputtering at edges.

-

Colors are average in saturation and contrast is relatively gray, but it is the first choice for DIY.

-

-

UV Printing:

-

A printing process that cures ink via ultraviolet light.

-

Ink is thicker with good adhesion. Printing on acrylic creates a textured, embossed feel. Close inspection reveals grain/noise, and ink edges are softer.

-

Colors have high saturation and are dense; contrast between light and dark is high, but transitions can be stiff. Suitable for small quantity customization and strict budgets.

-

-

Offset Printing:

-

Generally refers to lithography; the most common method for custom acrylic standees wholesale.

-

Ink is thin and blends well with the material, feeling smooth and non-fading. High printing precision allows for zero dot/noise visibility. Ink colors are slightly more muted than UV.

-

While saturation is lower, color transitions are more natural and details are clearer. This is the standard process for “Official Merchandise.” It requires plate-making fees, so MOQs (usually 500+) are needed for it to be cost-effective.

-

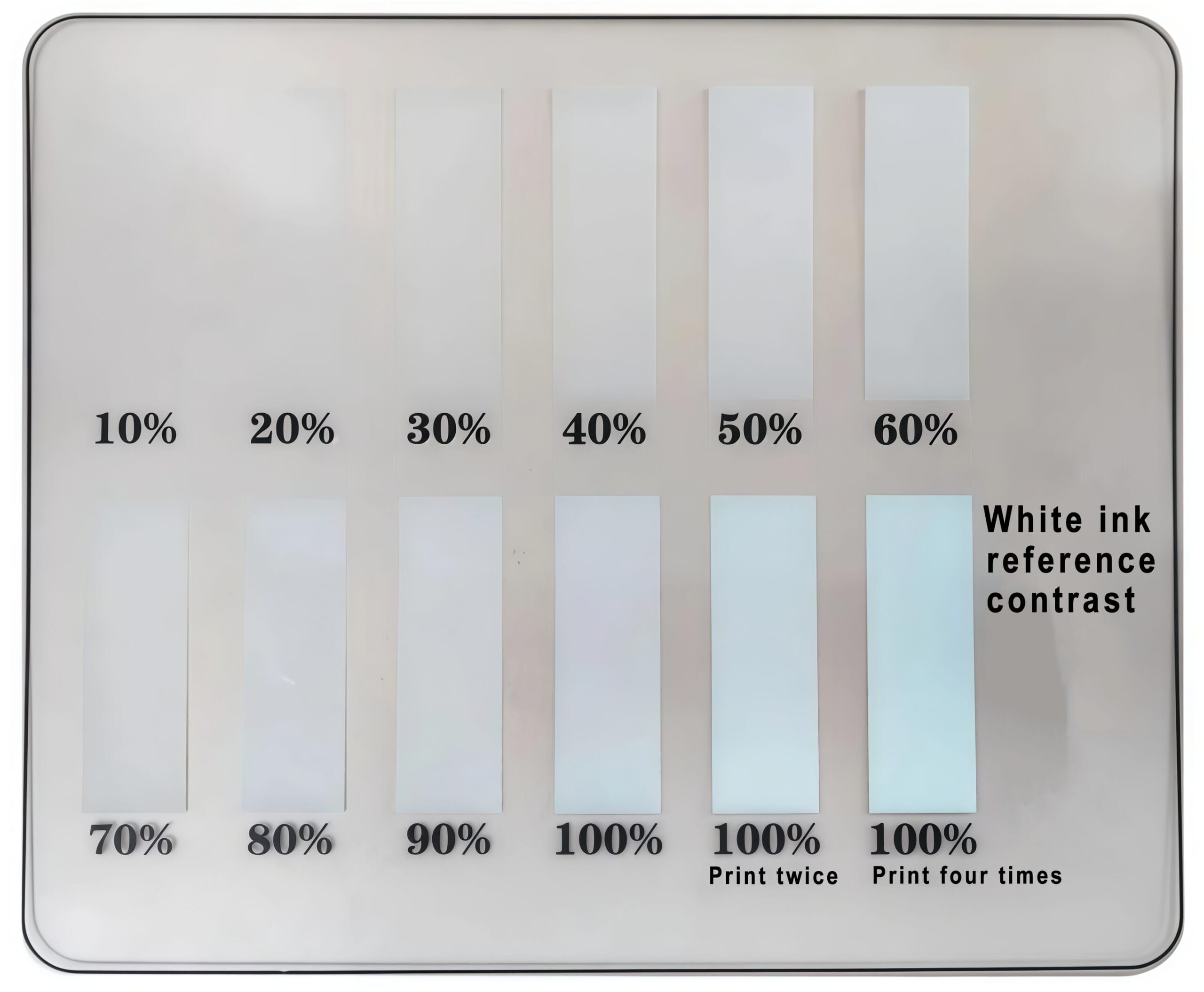

Ink Thickness & White Ink Contrast

The thickness of the ink affects its light transmission. By adjusting the thickness of the ink, you can create spatial depth, virtual-real contrast, and stained-glass effects. (Reference: 10% to 100% white ink opacity).

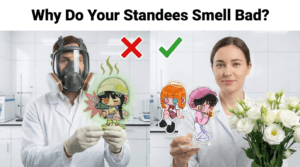

V. Cutting Processes (Laser vs. CNC)

1. Laser Cutting

-

Essentially thermal melting cutting.

-

For acrylic materials, the cut edge does not change color and has decent gloss. However, the edge quality will have tiny water-ripple knife marks and beading (rolled edges). There will be a burnt smell after processing, which dissipates with ventilation.

-

The first choice for small batches and low cost, suitable for strict budgets.

2. CNC Diamond Polishing (Carving)

-

Refers to precision cutting with tolerances up to 0.005.

-

High penetration, no rolled edges or knife marks. The side can be made perfectly smooth. Before polishing, the edge has a fogged look, but polishing processes increase transparency.

-

Limitation: CNC tools are thicker, so the cut gaps are wider, and it cannot cut sharp internal right angles.

-

Production time is slower than laser cutting, and costs are higher.

Cutting Comparison

| Feature | Laser Cutting | CNC Carving |

| Edge | Tiny knife marks, rolled edges | Smooth |

| Smell | High-temp cutting, burnt smell | Odorless |

| Limitations | Cannot do chamfering | Cannot cut internal right angles or chamfers |

| Time | Short | Long |

| Cost | Low | High |

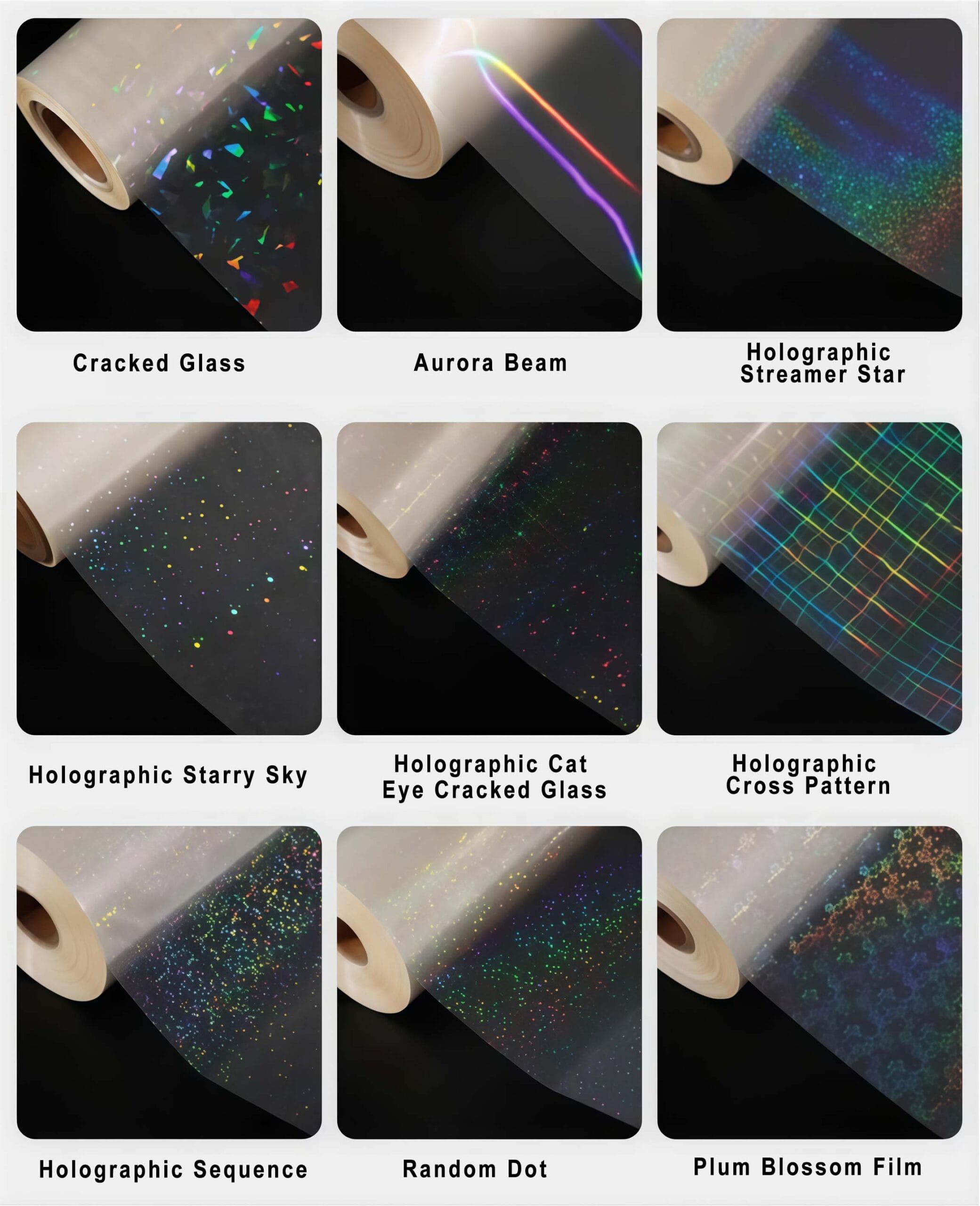

VI. Special Film Crafts (Lamination)

Definition: This is a post-printing finishing technology where an adhesive-coated plastic film is bonded to a paper-based printed product through heating, pressing, and cooling processes. This technique covers the printed surface with a transparent plastic film layer (typically 0.012-0.020mm thick), creating a unified, integrated paper-plastic product.

How to Prepare Your Art File for Flawless Printing?

To ensure your acrylic standees look exactly as crisp and vibrant as they do on your screen, starting with the right file is crucial. Here are the factory standards we recommend for the best results:

-

File Format: .PSD (Photoshop) or .AI (Illustrator) are preferred. These formats allow us to separate the “white ink layer” and “cutlines” precisely. High-quality transparent .PNG is also accepted.

-

Color Mode: CMYK. While screens display in RGB, industrial UV printers use CMYK ink. Designing in CMYK prevents unexpected color shifts and ensures your merch is true-to-color.

-

Resolution: 300 DPI (Minimum). This is the secret to “High Definition” printing. Anything lower (like web images at 72 DPI) will look blurry or pixelated when printed physically.

Not Sure Which Craft Suits Your Design?

Reading about “Diamond Polishing” and “Epoxy Doming” is one thing—seeing it in person is another.

We are so confident in our quality that we invite you to start with a sample kit or a small trial order. See why global creators trust BoceGifts as their manufacturing partner.