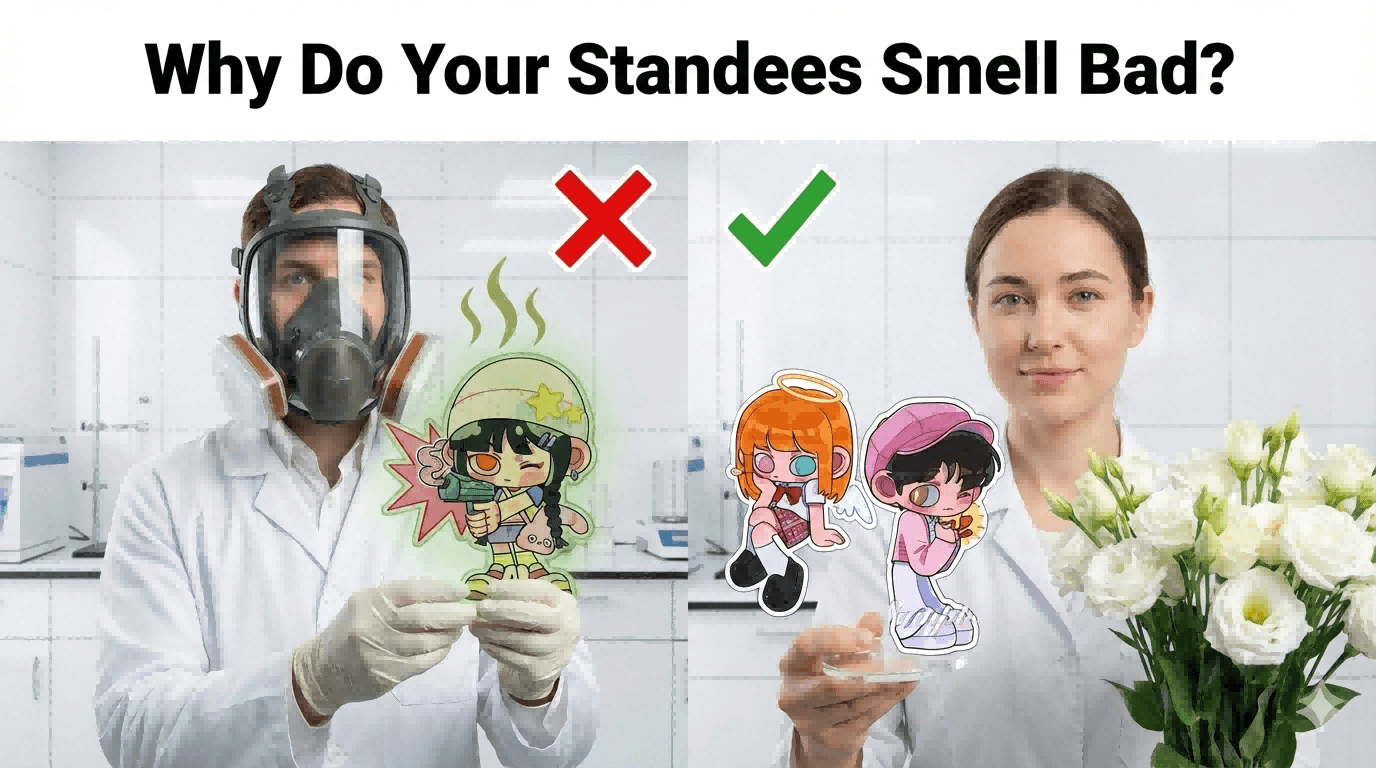

Have you ever opened a package of Custom acrylic standees wholesale expecting joy, but instead got slapped in the face by a sharp, nail-polish-remover smell? 🤢

That, my friend, is the smell of “cutting corners.”

As a professional acrylic standee manufacturer, we often hear clients ask: “Why are some standees odorless, while others smell toxic?” The answer lies in the VOCs (Volatile Organic Compounds). Basically, it’s a battle between Cheap Ingredients vs. Premium Materials.

Here is the breakdown of the “Stink Sources” and how Bocegifts eliminates them.

1. The “Zombie” Plastic (Recycled Materials)

The Problem: Acrylic (PMMA) should be odorless. But many cheap factories use recycled scraps or “regrind” materials to save cost.

-

The Science: Recycled material contains high levels of residual MMA monomers (Methyl Methacrylate). It smells sharp, pungent, and stays around forever.

-

The Reality: It’s like cooking with bad leftovers. No matter how much spice you add, it still smells off.

✅ The Bocegifts Solution: We Refuse “Trash” Plastic. As a top-tier Custom merchandise manufacturer, Bocegifts uses 100% Virgin PMMA. Our raw sheets are pure, with zero recycled content.

Result: No residual monomers = No headache-inducing smell. Just the fresh scent of quality.

2. The Toxic Glue (Cheap Assembly)

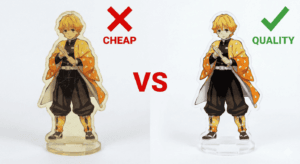

The Problem: If you are looking for a Custom acrylic figure maker, watch out for the glue!

-

The Science: Cheap factories use solvent-based glues full of Acetone, Toluene, and Ethyl Acetate to bond the character to the base.

-

The Reality: These solvents are volatile and nasty. They don’t just smell bad; they are bad for you.

✅ The Bocegifts Solution: Eco-Friendly Bonding. As a responsible acrylic standee supplier, we use:

Industrial Shadowless UV Glue: It cures instantly under UV light, locking in the bond without releasing toxic fumes.

Smart Interlocking Designs: Whenever possible, we design Bulk acrylic standees with precise mechanical fits (slots) that require NO glue at all.

3. The “Rush Hour” Mistake (Lack of Curing)

The Problem: Freshly printed and cut acrylic needs to “breathe.”

-

The Science: The Acrylic standee printing service (UV printing) and laser cutting process generate heat and temporary odors. If a factory packs them immediately into sealed bags to rush shipment, those smells get trapped.

-

The Reality: It’s like putting hot, sweaty gym clothes directly into a plastic bag. Not good.

✅ The Bocegifts Solution: The “Spa Day” for Standees. We don’t rush. After production, our products undergo a Ventilated Curing Process (24-48 hours) in a dust-free environment. We let the VOCs dissipate fully before we seal them in OPP bags. When your customers open their Acrylic charm manufacturer order, they smell… absolutely nothing.

4. The Additive Trap (Bad Colorants)

The Problem: Some colored or special-effect acrylics rely on cheap plasticizers or fluorescent agents that release odors when heated by the laser cutter.

✅ The Bocegifts Solution: Certified Safe Additives. We source our colorants and additives from certified suppliers. Our materials are Non-Toxic and RoHs Compliant. Your safety is our priority.

🎯 Conclusion: Don’t Let Your Brand “Stink”

A smelly product implies “cheap” and “unsafe.” Don’t risk your reputation on recycled materials.

At Bocegifts, we combine Virgin Materials + Eco-friendly Glue + Proper Curing to ensure your custom merch is safe, odorless, and premium.